High-Speed Nitrogen Hood for PET Filling Oxidation Control

High-Speed Nitrogen Flushing System N₂ Hood

DNP’s N₂ Hood is an in-line, hooded module that purges over 90% of headspace air with sterile nitrogen—even at 72,000 bottles per hour (BPH)—preserving taste and nutrients while reducing oxidation-related losses. It is the ideal choice for producers seeking both maximum efficiency and uncompromised product quality.

Table of contents

|

|

What is nitrogen flushing? — Why it is essential for aseptic filling lines

Oxygen in the headspace of a bottle can cause oxidation, shorten shelf life, and impair flavor. This is especially true for bottles with a 38 mm mouth diameter and lightweight PET bottles, where the amount of oxygen in the headspace has a significant impact on shelf life. Nitrogen filling replaces this oxygen with sterile N₂, thereby maintaining the taste of the beverage for an extended period. For tea, lemon juice, and other sensitive beverages, this low-O₂ zone is essential—but conventional open-jet purging systems can't hit a reliable target at today’s high line speeds, causing bottle-to-bottle variation.

What is the new nitrogen flushing solution N₂ Hood?

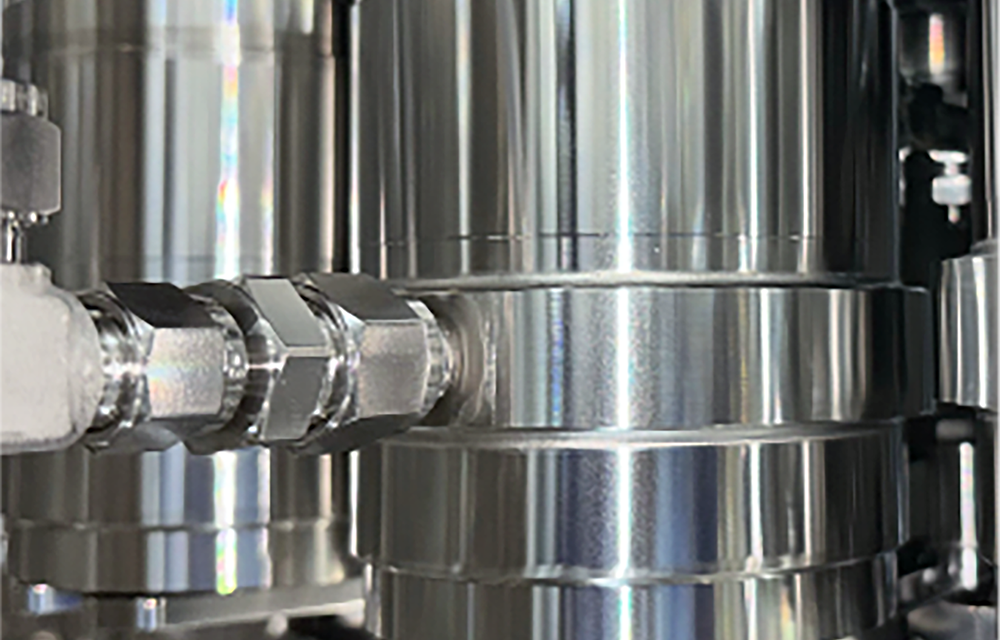

N₂ Hood is an in-line nitrogen-flushing module that surrounds each PET bottle with a dedicated hood immediately after filling, displacing over 90% of the headspace air with sterile N₂ before the cap is applied.

|

|

How N₂ Hood works

1. Aseptic filling

The PET bottle is first filled with product under sterile conditions, establishing the baseline for low-oxygen packaging.

2. Nitrogen jet at the capper

As the filled bottle enters the capper, a targeted jet of nitrogen gas is directed across the mouth of the bottle, displacing the ambient air.

3. N₂ Hood purge & torque-sealing

A dedicated nitrogen hood immediately covers the top of the bottle, continuously flushing the enclosed space with nitrogen while the cap is torqued on.

Key features

- N₂ replacement rate: Approximately 90% (varies by product)

- For foam-prone products, N₂ can also be applied before filling.

- Proven Operational Capacity: 48,000 to 60,000 BPH

Advantage: Over 90 % nitrogen replacement at high speeds

The N₂ Hood is engineered for today’s ultra-high-speed PET lines, delivering consistent, deep headspace nitrogen insertion to prevent oxidation. As each filled bottle enters the capper, a compact hood drops over the neck and releases a concentrated jet of sterile nitrogen—targeted precisely where it matters. This process displaces over 90% of the ambient air, even at speeds of up to 72,000 BPH.

By confining the purge zone to a micro-chamber, the system minimizes nitrogen consumption while ensuring a uniform, ultra-low-oxygen headspace across the entire production run.